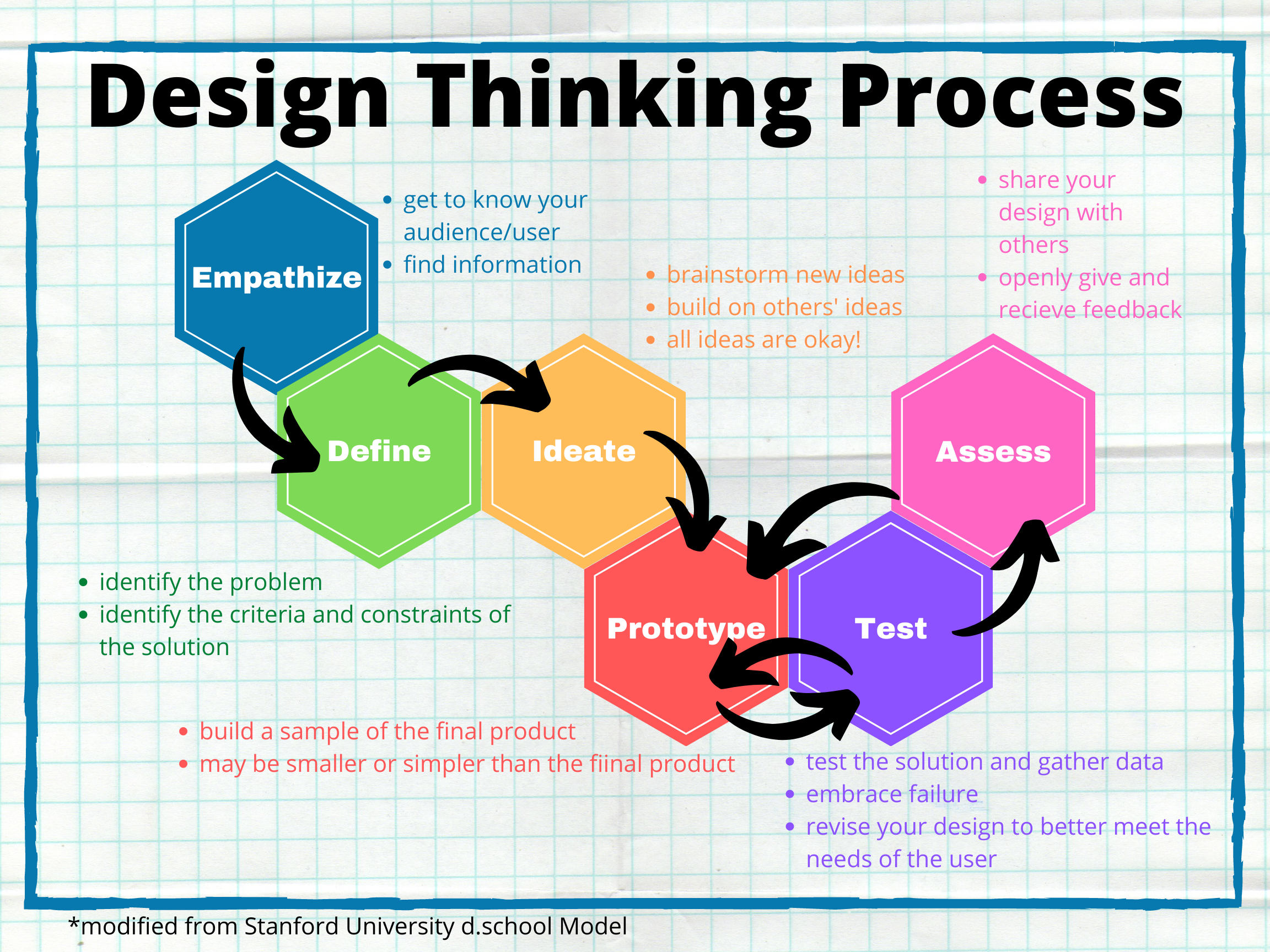

Design Thinking in Action

Design Thinking happens all around us. Let’s look at some ways Jordan and some of his ASA students have applied this year.

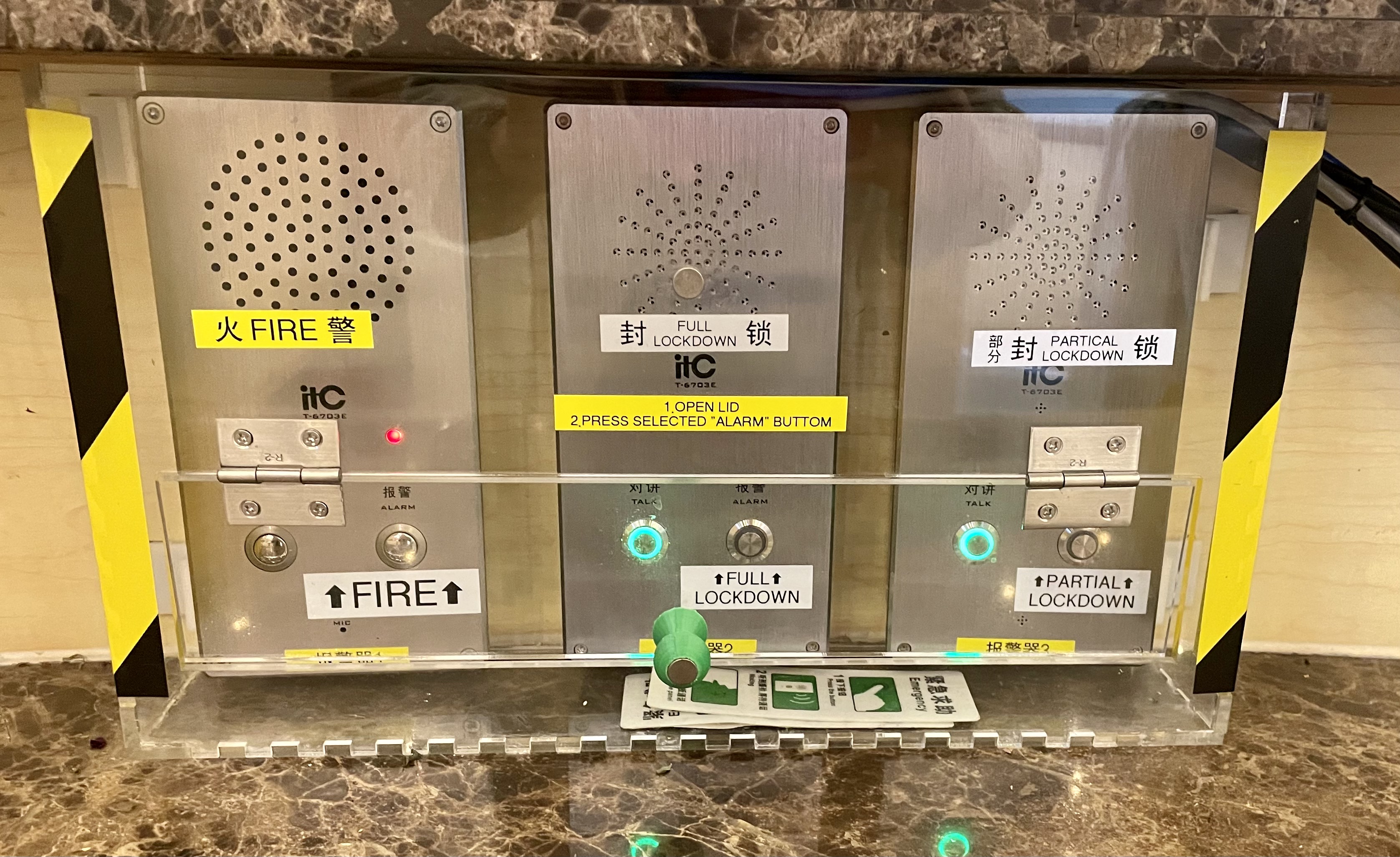

Alarm Cover

Back in November, you might remember when the alarm was accidentally triggered. The emergency alarms are tucked under the counter at the receptionist’s desk. Over the summer we added the additional options for full lockdown and partial lockdown. You can see from the image below that they are completely exposed and accessible.

After an hour of measuring and data collection, design sketches were made. Then a detailed digital design was made before cutting the acrylic pieces on the laser cutter.

After a few rounds of testing for fit, the assembly and installation were complete. Now the alarm buttons are secure!

Sharp Objects Lock Box

After observing that the check-out system for the box cutters was too reliant on the honor system. A redesign was in order.

A lockbox was designed to keep sharp objects more secure. This also improved traceability for students using the box cutters.

Jordan followed the same plan as in the Alarm covers: sketch, digital design, laser cutter.

While the box cutters and sharp objects are more secure, there is still an issue with the slots being too tight and the check-out sheet needs refining. There is always room to improve systems!

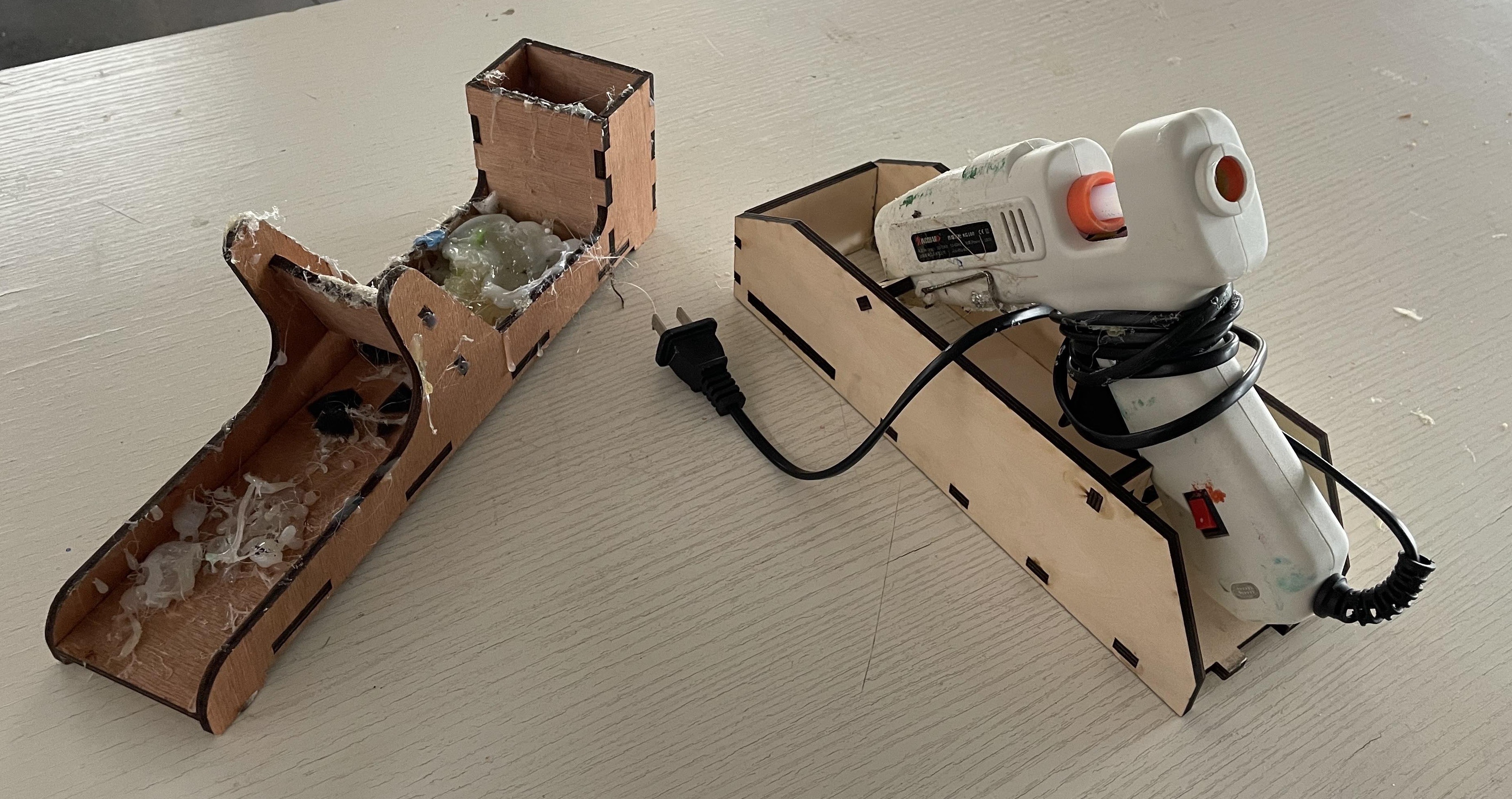

Hot Glue Gun Holders

Design Thinking often starts with identifying a problem. This project started with piles of glue guns left in the cabinet and tables covered in hot glue. Glue guns can be messy, especially after a group of students filter through the InnoHub. A storage solution was in order. The goal of the first model was to keep them neatly stored in the cupboard, catch the glue when not in use, and hold extra glue sticks. Design 1 accomplished that.

After using them for a semester, Jordan noticed they were filled with excess hot glue. A redesign was in order to make the racks last longer with a removable glue catcher. Two more prototypes were made. Neither has worked as well as the original.

When will the next prototype come out?

Wood Storage

At the start of the Woodworking ASA, Jordan received the lumber for the whole trimester and had nowhere to store it. He posed this problem to his ASA students in the spring of 2021 to design a solution. The parameters were: mobility and accessibility while accommodating all sizes of wood. Due to the shorted year in spring 2021, the students that designed it did not build it. In working towards building the original design, this year’s students have made alterations to adapt to their needs.

Students have plans to add pegboard for tool storage to the face of the cart. This will make tools handy and declutter the tool cart in the InnHub main space.